Replace or Repair a Victor Pool Table Ball Return System

9/8/2017 6:28:13 PM

Replace or Repair a Victor Pool Table Ball Return System

My grandfather had a Victor pool table custom build in 1970 and now the table belongs to me.

I'd like to know how to restore or replace the ball return system, which is now in disrepair.

Since the company is defunct does anyone know how I might be able to do this?

Replace or Repair a Victor Pool Table Ball Return System

Replies & Comments

O2doc on 1/16/2020 7:11:00 AM

O2doc on 1/16/2020 7:11:00 AMI just finished resurrecting my Victor Cleveland pool table, circa 1930, after it spent 3 decades in pieces in my basement.

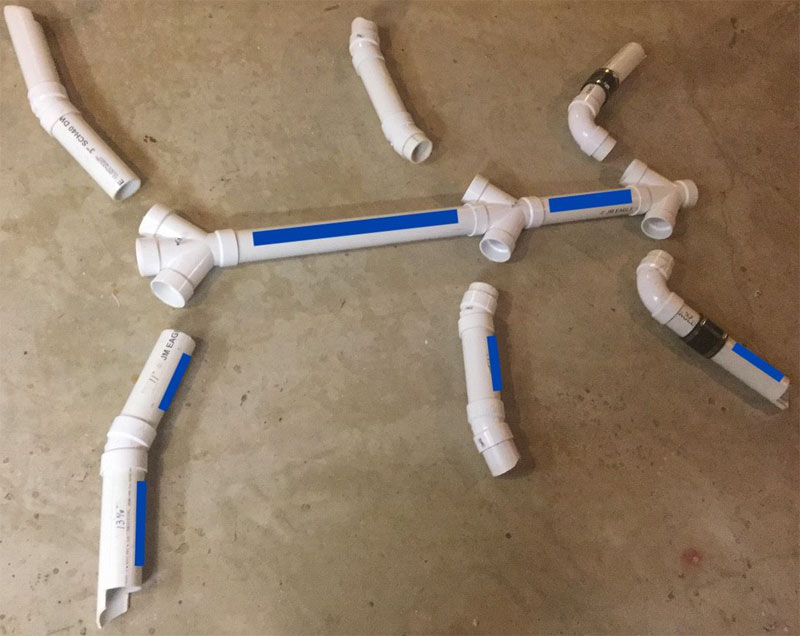

Like you, I was faced with a deteriorated original (Frank Lanza patented) ball return. After touching base with Ed Lanza, I decided to go rogue, and was able to fabricate a return using 3” PVC for < $ 120 from the box store.

If you haven’t yet solved your problem, I can provide you additional construction photos, inclusive of one that is effectively a measured drawing.

As you mentioned 1970 and custom build, the concept might apply but the sizing/measurements likely won't exactly.

j3nineball on 3/15/2020 6:27:33 PM

I just bought a Victor pool table just like the one you posted here.

Can you provide me with any pictures and/or advice on taking it apart and putting it back together?

O2doc on 3/16/2020 6:06:15 AM

O2doc on 3/16/2020 6:06:15 AMUnfortunately, I didn't take or keep any photos that might be of help as to the general aspects of assembly or disassembly. The pix I compiled were specific to the novel ball return system, and can be found as a PDF link within my 1/18/2020 post to the below thread.

When doing the overall assembly, I thought that things were reasonably "self-evident," and I guess I was right because my table still stands (as of now!).

If you've got particular questions regarding particular components, post some photos, and I'll give you the best input I can under the circumstances.

billiardsforum on 3/16/2020 7:09:53 AM

billiardsforum on 3/16/2020 7:09:53 AMWhat a great solution you've created to replace a failing ball return.

I love the use of those black flexible rubber couplings to accommodate the slightly irregular angle needed to run the pipe up to those corner pockets.

One could solve the noise issue by cutting the PVC in half (since you only really need the bottom half) and lining the bottom of the pipes with a thin rubber or other material.

O2doc on 3/16/2020 8:04:53 AM

O2doc on 3/16/2020 8:04:53 AMI agree that “halving” the PVC would facilitate rubber/felt/other lining placement for noise reduction. It would also facilitate routine cleaning or trapped ball retrieval. (BTW: I’ve played dozens of racks without a stuck ball.) I don’t think it would significantly compromise structural strength, the need for which is modest in the first place.

An alternate to outright halving perhaps would be to cut PVC “slits” as per blue rectangles in the attached photo, to retain more of the circumference and structural strength, especially at the (non-cemented) joints. It could probably be done without terrible difficulty using standard table saw and/or other saw.

user1610333597 on 1/10/2021 6:53:21 PM

Do you happen to have the PVC measurements for replacing the ball return on a 9-foot Victor pool table?

O2doc on 1/11/2021 9:01:43 AM

O2doc on 1/11/2021 9:01:43 AMHere are the fabrication instructions for my PVC ball return system (and it is about 7 MB so let it load).

PVC Pipe Ball-Return for Pool Tables (PDF)

See page two for the PVC measurements.

RayMills on 2/6/2021 2:04:22 PM

RayMills on 2/6/2021 2:04:22 PM@O2doc, I will dare to ask the question that so many of us want to have answered:

How silent is the new PVC ball return system?

My ball return quieting project is set for this spring, but I won't be installing any PVC. I probably won't cover any surfaces of the return channels, either, but I wonder how much a full pipe constrains or trumpets noise that a half pipe would release. My loudest bangs are when the balls get some speed up and are turned sideways to fall into the display box. (I'm on a free-play 8-foot coin-op pool table.)

O2doc on 2/7/2021 6:27:33 AM

O2doc on 2/7/2021 6:27:33 AMHow loud? That’s a tough one to answer absent attaching a short video/audio file. Attachments to the forum are evidently limited to docs and pics. However, see the attached pic, courtesy of an iOS free app dB meter.

My pool table sits in an open unfinished basement near a furnace. Via an iPod table-side mic, baseline “silence” registers 31.9 dB. The max noise of a single ball dropping into a pocket is:

76.5 dB - 31.9 dB = 44.6 dBThe relative noises of subsequent events can be eyeballed on the waveform. It’s certainly not silent, but I’ve felt no need to attempt post-hoc noise reduction e.g. padding the PVC.

Whether the closed conduits amplify sound more than if they were open is an interesting question. I don’t have enough acoustics skill or intuition for an educated guess. The experimental method—just cutting away some of the tubing and testing—would provide the answer, but I’m just not that motivated.

billiardsforum on 2/7/2021 9:36:44 AM

billiardsforum on 2/7/2021 9:36:44 AMIt's an awesome DIY ball return system, and great discussion.

I'd think the prolonged "sounds" of pocketing one or more balls would suit me just fine!

That extra noise is because you just pocketed a ball. It seems like it would prolong that inner-victory you feel, and perhaps extend the dopamine hit you feel when a ball rattles into a pocket.

@O2doc - I sent you an email about the audio file...

O2doc on 2/8/2021 5:55:29 AM

O2doc on 2/8/2021 5:55:29 AMYour “dopamine hit” hypothesis for the sounds of pocketed balls makes sense.

The darker side: The same thing likely reinforces little old ladies at Atlantic City slots who get “rewarded” by pleasant bleeps and jingles each time they pull the lever --and even more so on a jackpot. At least the pool player relies on skill and the slot player merely luck!

... and the pool player at home is expending merely time and not coins!

RayMills on 10/12/2021 7:23:32 AM

RayMills on 10/12/2021 7:23:32 AMThanks for your reply, @O2Doc. I believe this is the first time I've seen it since you answered me 8 months ago!

I made an attempt to quiet my Global barbox pool table and I'm 80% happy with the results. I deduced that the best overall method to reduce noise was to reduce the speed of the balls. So, I used some yoga-mat foam to coat corners and intersections of the metallic center trough to:

- Cause some minimal resistance against the balls which get launched almost unabated from the head pockets;

- Stop balls from the side pockets from colliding with the metal at right angles; and

- Keep the foot-pocket balls from going airborne when then enter the collection box which diverts all balls toward the window display.

Whenever I built some resistance, I tried to make the balls go a little uphill.

So, I'm still looking for complete silence.

Can you measure or estimate for me how far apart the 4 inner tracks were on the original ball return tubes on your Victor pool table? I'm guessing that 2.25" balls have a 7" circumference, which would suggest 7/4 inches, but I don't know how that works practically. I might still try the patents' ideas with updated materials.

Thanks again for sharing your experience.

O2doc on 10/12/2021 11:21:10 AM

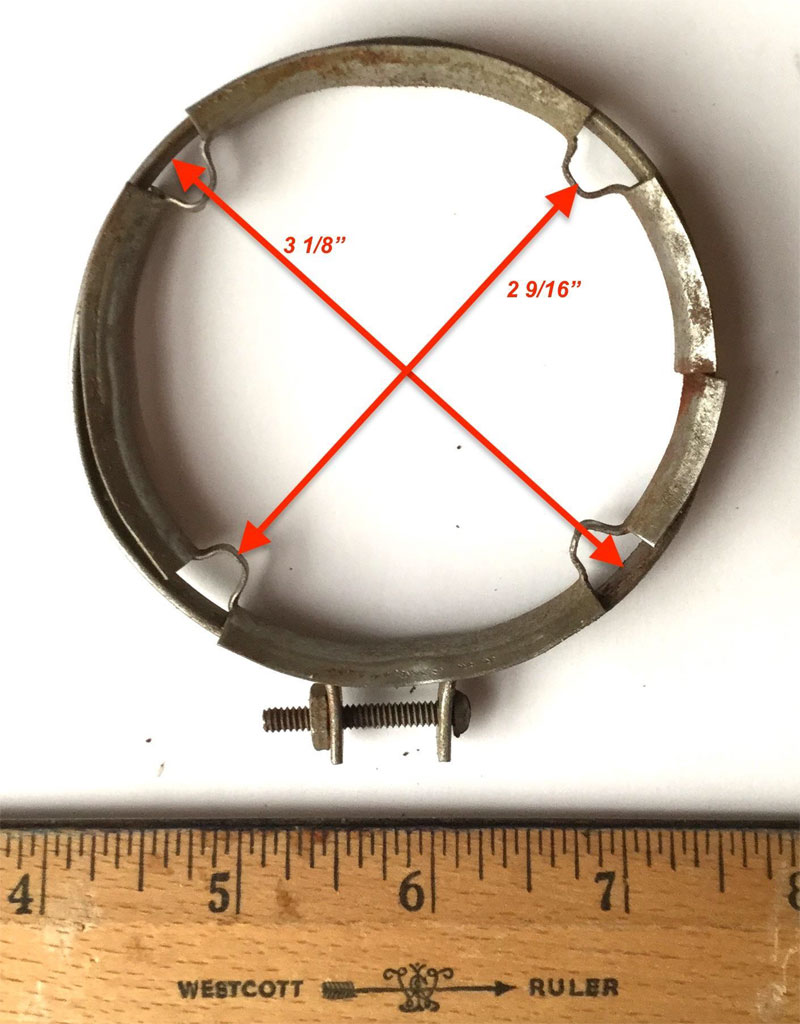

O2doc on 10/12/2021 11:21:10 AMI'm not exactly sure of what you're asking for, but I suspect the attached photo might give you a ballpark. It's one of the original clamps that maintained the 4 rubber-coated tracks in proper spacing and alignment.

I long ago discarded the tracks themselves. My best guesstimate is 2 1/2" for the track-to-track (rubber-to-rubber) ball pathway diameter of the trackway.

Hope this helps!

RayMills on 10/13/2021 4:21:43 AM

RayMills on 10/13/2021 4:21:43 AMFantastic! That ruler was truly a bonus to the photo!

I measured 1.75" from the tip of the lower-left loop to the lower-right one, and then only a minimally longer space straight up to the upper ones. My 7/4 guess was around the ball's surface, but I was only slightly short. I assume the balls touched only two tracks at any given moment as they progressed, and they otherwise needed to be tightly controlled for silence.

Because you said "rubber coated", I'm going to start with tracks of insulated electronic wire or an exaggerated version thereof.

Did the tracks run within the loops, with the rubber outside of them?

I forecast a fun trial-and-error experiment!

Thanks again, and be sure to stop in to see the results next time you're north of Seattle.

Want to sell me some clamps?

O2doc on 10/13/2021 6:45:38 AM

O2doc on 10/13/2021 6:45:38 AMGlad I could help, and your assumption sounds reasonable.

Those four small loops did contain the rubber-coated track wires. The rubber in its original state was sufficiently thick and pliant as to allow the metal crimps/pinches to "hide" below the level of the surrounding rubber. Absent this, there would be audible traumatic ball strikes on each transit.

On discussion I had with Ed Lanza a couple of years ago, his opinion was that modern plastic/polyethylene/etc would not cut the mustard as a viable coating as such material is too stiff. He had "old fashioned" neoprene rubber replacement tubing available at a quoted price per foot that I wasn't agreeable to. (Being a cheap DIY son-of-a-B, I went with my improvised fix instead.)

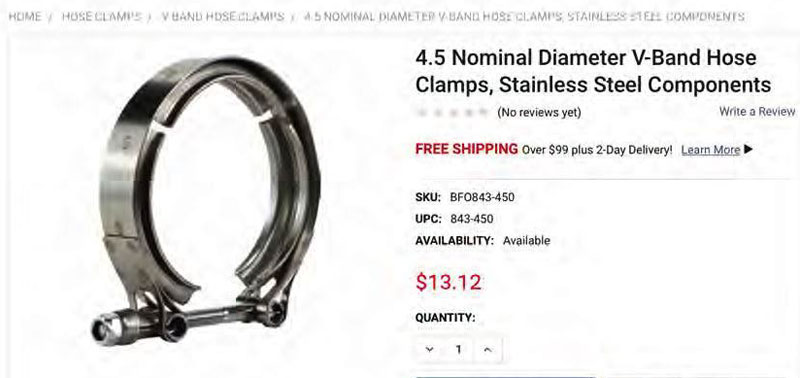

I was led to believe the clamps aren't manufactured anymore, anywhere. I once looked for an equivalent; see attached photos for the closest I could find. See also attached for what I've kept. It's a high enough res pic to allow some reasonable inspection. I had acid bathed and wire wheeled off all the original rust that I could. You can have 'em for $2 ea if you'll eat the shipping.

Drop me an email having your phone number to

marianip@upstate.eduand we can discuss further if you like. RayMills on 10/13/2021 7:52:56 AM

RayMills on 10/13/2021 7:52:56 AMOkay, I'll let you know when I find out if I'm simply going to use the existing channels as support for the silent tracks, and whether I have to build six separate paths, etc.

Looks like I'm going to have to find another way to slow down the balls.

mikeruff on 11/21/2023 1:03:28 AM

I love the creativity and precision of information that I've found here.

Wold the PVC pipes not scratch or damage the balls? I mean the surface isn't smooth (as compared to imperial cardboard tubes).

Just curious.

O2doc on 11/21/2023 9:53:32 AM

O2doc on 11/21/2023 9:53:32 AMCAVEAT: I'm not a materials scientist/engineer.

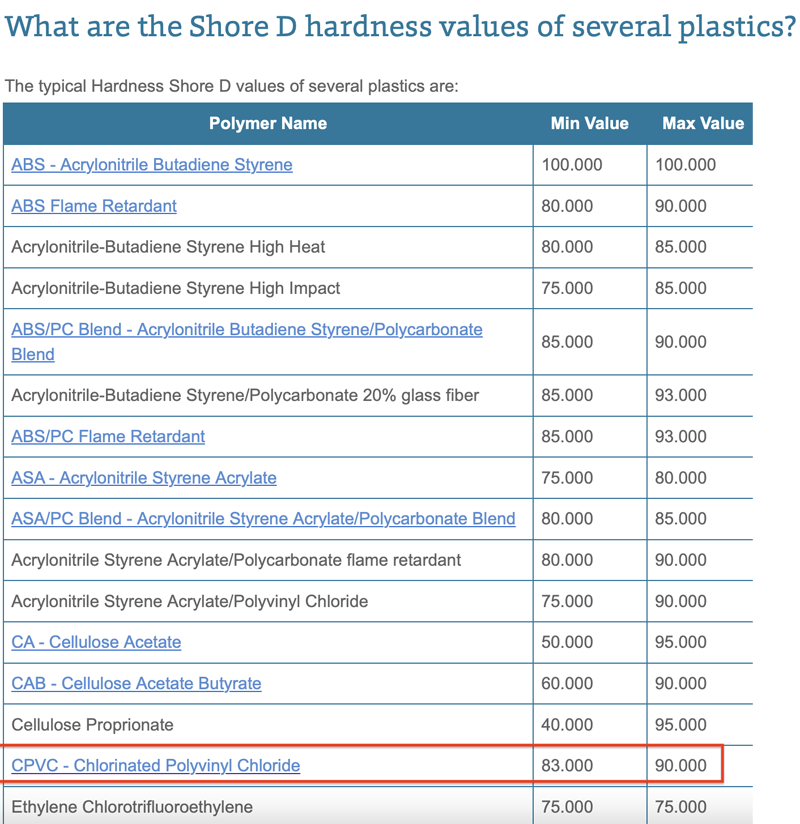

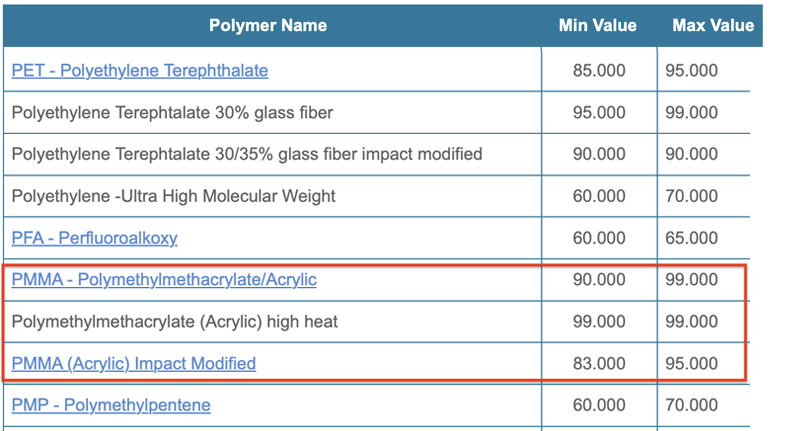

I can say empirically that I've observed no marring or pitting to my billiard balls after years of PVC pipe transits. There remains, however, a theoretical risk, and my layman understanding is that it comes down to a matter of hardness of the particular ball vs. the particular pipe. See references below as to some Shore Scale figures. Balls can be made of many things and modern ones are likely Acrylic (aka PMMA). Typical schedule-40 PVC is made of CPVC. On my cursory search this morning, ranges can overlap. Ditto if the balls are of natural ivory!. So the concern is reasonable, and cloth/felt/rubber flooring on the PVC could mitigate risk—as wells as transit noise.

I'd speculate that ball manufacturers would formulate products to optimize hardness so there's likely less risk, and the above could be a worst case scenario.

See...

General discussion of material hardness - omnexus.specialchem.com/polymer-properties/properties/hardness-shore-d

Interesting measurement demonstration using ivory:

mikeruff on 11/21/2023 12:37:56 PM

That helps!

I was actually looking at something like these heavy duty cardboard mailing tubes (from amazon.com) and was thinking how to make it work in some way.

It seems like the CPVC pipes are actually smoother on the inside. Maybe that is it, I think.

Thank you for that in-depth insight!

O2doc on 11/21/2023 2:49:34 PM

O2doc on 11/21/2023 2:49:34 PMYou're welcome!

Standard PVC is actually very smooth on the inside and likely sufficiently softer than the ball.

The upside of using cardboard tubing is that it is certainly softer—and likely less noise generating—and probably stout enough to avoid sagging with the lengths demanded of it. One caution; If your pool table location is damp (e.g., a typical basement), then over time the cardboard could absorb enough moisture to lose some stiffness and start sagging of its own weight or on strains of repeated ball transit.

Replace or Repair a Victor Pool Table Ball Return System

- Title: Replace or Repair a Victor Pool Table Ball Return System

- Author: user1504909692

- Published: 9/8/2017 6:28:13 PM

- Last Updated: 9/9/2017 10:46:43 AM

- Last Updated By: billiardsforum (Billiards Forum)